Conveyors - ESD Work Table

Conveyors and ESD work tables are two separate types of equipment commonly used in manufacturing and assembly environments.

Conveyors are mechanical devices used to move materials and products from one place to another. They are used in a variety of industries, including manufacturing, food processing, and packaging. Conveyors can be designed to move products vertically or horizontally, and they can be automated or operated manually.

ESD work tables, on the other hand, are specialized work surfaces designed to prevent damage to electronic components and assemblies from electrostatic discharge (ESD). These tables are typically made of materials that are conductive or dissipative, which helps to prevent the buildup of static electricity that can damage sensitive electronic components.

While conveyors and ESD work tables serve different functions, they can be used together in certain manufacturing and assembly environments. For example, in the production of electronic devices, conveyors can be used to move products between different workstations, and ESD work tables can be used at each workstation to protect electronic components from damage.

Overall, both conveyors and ESD work tables play important roles in the manufacturing and assembly process, and using them together can help to improve efficiency and protect valuable electronic components.

Mould / Die Storage Rack

A mould/die storage rack is a specialized type of storage system designed to organize and store moulds or dies used in manufacturing processes. These racks are typically made of heavy-duty steel or other durable materials to support the weight of the moulds or dies. They are designed with compartments or shelves that are sized and configured to accommodate various types and sizes of moulds or dies. Mould/die storage racks can help to optimize floor space in manufacturing facilities by keeping the moulds or dies organized and easily accessible. They also help to protect the moulds or dies from damage and extend their lifespan by keeping them stored in a safe and secure manner. These storage racks are commonly used in industries such as automotive, aerospace, and plastics manufacturing.

Motorized Roller Extendable Conveyor

A motorized roller extendable conveyor is a type of conveyor system that uses motorized rollers to move products or materials from one place to another. The extendable feature of this conveyor allows it to expand or contract in length to fit the specific needs of a particular application.

This type of conveyor system typically consists of a series of motorized rollers mounted on a frame. The rollers are powered by an electric motor, which drives the movement of the conveyor belt. When the conveyor is extended, the motorized rollers can be set to specific speeds to move products smoothly along the length of the conveyor.

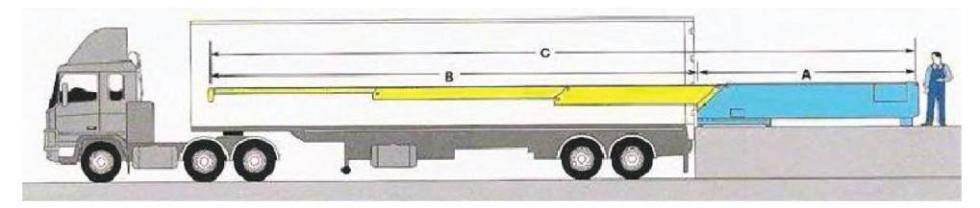

Telescopic Conveyors

Telescopic conveyors are a type of material handling equipment used to move products or materials in a linear direction. They are designed to expand and retract in length to fit the specific needs of a particular application.

Telescopic conveyors typically consist of several sections or stages that can be extended or retracted by a hydraulic or mechanical system. The sections are mounted on a frame and are designed to slide in and out of each other. The conveyor belt is typically mounted on the last section of the telescopic conveyor, allowing it to move products or materials along the length of the conveyor.

These conveyors are commonly used in loading and unloading applications, such as in warehouses, distribution centers, and shipping facilities. They can also be used in assembly lines and production lines to move products between different stages of the manufacturing process.

The telescopic feature of this conveyor system allows it to be customized to fit the unique needs of a particular application. They can be extended or contracted to fit specific loading or unloading areas, or to accommodate products of different sizes or shapes. This type of conveyor is versatile and can be used in a variety of industries, including automotive, food processing, and packaging.

Spiral Gravity Roller Conveyor

A spiral gravity roller conveyor is a type of material handling equipment used to move products or materials in a circular path using gravity. It consists of a series of parallel rollers mounted on a spiral frame that allows products or materials to move smoothly from one level to another.

As the products or materials move down the spiral gravity roller conveyor, the force of gravity causes them to roll down the rollers to the next level. The spiral design of the conveyor allows it to occupy a smaller footprint while still maintaining a high throughput rate.

This type of conveyor is commonly used in applications where products or materials need to be moved from an upper level to a lower level, such as in multi-level warehouses or distribution centers. It is also used in production and assembly lines to transport products or materials between different stages of the manufacturing process.

The spiral gravity roller conveyor is designed to be flexible and adaptable to a variety of different applications. It can be customized to fit the specific needs of a particular application, including the number of levels, the length of the conveyor, and the diameter of the spiral frame. This type of conveyor is efficient, space-saving, and can improve the overall productivity of a manufacturing or warehousing operation.